Vibration analysis and balancing of rotor blades

Our services include the following:

» Measurement of imbalances on site

» Interpretation of measurement results

» Elimination of the rotor imbalance

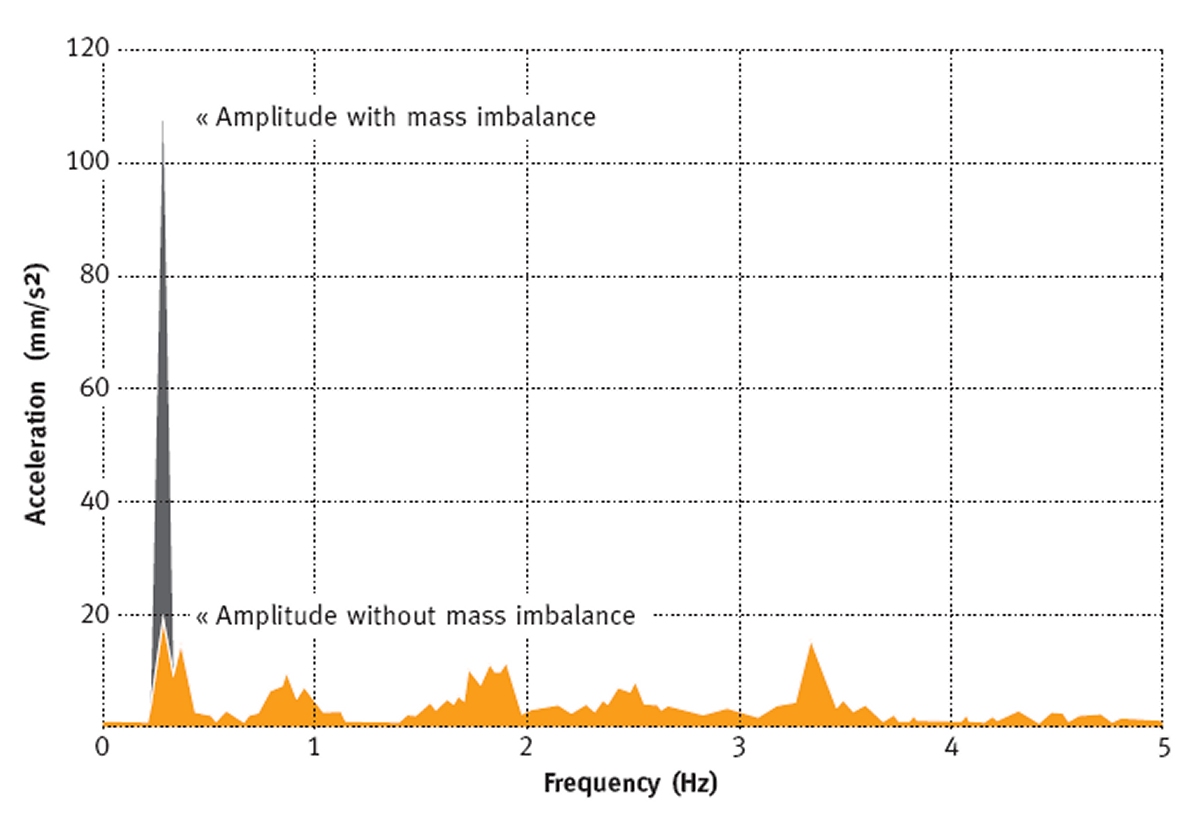

Imbalance vibrations – An often neglected problem

Wind turbines are susceptible to vibrations because of their dimensions and mass distribution. Vibrations appear on each wind turbine to a limited extend. But our experience showed that about 35 % of all wind turbines have rotor caused vibrations which exceed the acceptable limits. These vibrations cause unusual structural loads, increased wear, adverse start-up conditions and often vibration-caused turn offs.

Usually vibration-caused problems are detected too late or they are misinterpreted. An available CMS (condition monitoring system) is not always able to interpret the measured signals correctly. The reduction of energy yield and lifetime can be the cost-intensive consequence.

Causes of rotor imbalances – Diverse possibilities

Rotor imbalances on wind turbines can be differentiated in the two following types caused by several reasons:

|

Mass imbalances |

Aerodynamic imbalances |

|

|

|

|

|

|

|

|

|

|

Indication and elimination of imbalances – Our special field

We support our customers in preventing the negative effects of imbalances and offer a complete service package. This package includes several parts. First we run the measurements on site. On base of our long-term experience we interpret the measurement results and provide our customer a recommendation of measures. Finally we are able to eliminate the imbalance if necessary. Our customers benefit from the big advantage that we are able to handle the complete balancing process.

In order to provide a trouble-free and reliable operation of your wind turbine, the balance conditions of the rotor blades should optimally be analysed regularly, especially after repairs. At least it should be checked once in a life time right after installing the turbine. At this time an imbalance problem is detected early enough to be solved with low effort and costs.

A perfectly customised vibration meter

We have been balancing wind turbines for almost 20 years. Early we discovered that existing measurement technology from other areas had several disadvantages when used on a wind turbine. Many measuring devices work optimally in a different frequency range, they are complicated to use and have a very high purchase price.

These challenges motivated us to develop a vibration meter, which was specifically designed for wind turbines. It is easy to use and delivers precise results. You can learn more about it here.

Please click here for detailed information about the balancing process of the rotor.